lime based steam autoclaved fly ash bricks|seyitömer fly ash : advice Real-size fly ash/lime bricks were produced in a steam autoclave. Tobermorite and katoite were formed as binding phases in bricks. Single axis compressive strength of the bricks was 76.5 kg f/cm 2. . Eng. 2 (3) (1999) 191–197. [17] T. Çiçek, M. ve Tanrıverdi, Lime based steam autoclaved fly ash bricks, Constr. Build. Mater. 21 (2007 .

both the seed gel and mother gel solutions were thor-oughly mixed and continuously stirred for more than 30 min. Next, the mixed solution was transferred to a Teflon-lined, stainless steel .

{plog:ftitle_list}

Autoclave Use Guidance Document Page 2 of 8. The hot, pressurized steam generated by autoclaves presents a serious burn hazard. Conditions inside steam autoclaves can reach a .

Fly ash, sand and hydrated lime mixtures were steam autoclaved under different test conditions to produce brick samples. An optimum raw material composition was found to .Mechanical strength and water absorption properties of autoclaved fly ash-lime bricks, TMMOB, Chamber of Civil Engineers’ Publication, Vol. 1, pp. 385-394. In article [8] Cicek, T. and Tanrıverdi, M. 2007. Lime based steam autoclaved fly .

In general, for fly ash–lime bricks, . Cicek MT (2007) Lime based steam autoclaved fly ash bricks. Constr Build Mater 21:1295–1300. Article Google Scholar Deg˘irmenci N, (2008) Utilization of phosphogypsum as raw and calcined material in manufacturing of building products. Constr Build Mater 22:1857–1862

Lime based steam autoclaved fly ash bricks. tayfun çiçek. 2007, Construction and Building Materials. See Full PDF Download PDF. See Full PDF Download PDF. Related Papers. Journal of Minerals and Materials Characterization and Engineering .Keywords Fly ash Gypsum Lime Fly ash brick Compressive strength Steam curing 1 Introduction Fly ash is a product obtained by burning of powdered coal in thermal power plants. More than 160 million . examined the strength of lime based steam autoclaved fly ash bricks. The bricks cured at 1.5 MPa autoclave

Real-size fly ash/lime bricks were produced in a steam autoclave. Tobermorite and katoite were formed as binding phases in bricks. Single axis compressive strength of the bricks was 76.5 kg f/cm 2. . Eng. 2 (3) (1999) 191–197. [17] T. Çiçek, M. ve Tanrıverdi, Lime based steam autoclaved fly ash bricks, Constr. Build. Mater. 21 (2007 . Lime Based Steam Autoclaved Fly Ash Bricks Constr Build Mater, 21 (6) (2007), pp. 1295-1300. View PDF View article View in Scopus [6] Jin-rui Zhang. Utilization and resource recovery of tailings. Metallurgy Publishing House of Chinese, Beijing (2002) p. .

seyitömer fly ash

Fly ash, sand and hydrated lime mixtures were steam autoclaved under different test conditions to produce brick samples. An optimum raw material composition was found to be a mixture of 68% fly .

Autoclaved fly ash bricks, tiles, curb stones, blocks etc. and method of manufacturing the same are disclosed. In an embodiment of the present invention, there is provided a process of manufacturing fly ash bricks, wherein the pond ash or fly ash is used up to 92% with or without siliceous sand after mixing with burnt lime powder or hydrated lime power or sludge of . Another study that employed the method of curing under high pressure steam using the Seyitömer fly ash, slaked lime and sand at pre-determined ratios, also obtained encouraging results [17]. Recently, studies were conducted towards the leaching behavior of heavy metals from fired [23] and autoclaved [24] fly ash–lime bricks.

Lime based steam autoclaved fly ash bricks, Construction and Building Materials, Vol. 2 1, No. 6, pp.1295-1300. Çiçek, T. ve Tanrıverdi, M., Kömüre da yalı termik santral uçucu küllerinden .

Cicek and Tanriverdi [4] prepared lime based steam autoclaved fly ash bricks with the compressive strength of 10.25 MPa. Yang et al. [1] used phosphogypsum to prepare load-bearing autoclaved bricks, whose flexural strength and .

lime based fly ash

Clay Fly ash bricks Fly ash lime bricks Mud Fly ash bricks 2.1.1 FLY ASH LIME BRICKS In presence of moisture, fly ash reacts with lime at ordinary temperature and forms a compound possessing cementitious properties. After reactions between lime and fly ash, calcium silicate hydrates (C-S-H) are

Leachability of Heavy Metals from Autoclaved Fly Ash-Lime Building Bricks. M. Tanrıverdi G. Sen T. Çiçek S. Şen Öznur Önel. Environmental Science. Inżynieria Mineralna. . Lime based steam autoclaved fly ash bricks. T. Çiçek M. Tanrıverdi. Environmental Science, .Cicek and Tanrıverdi, (2007) studied with the lime based steam autoclaved fly ash brick and also investigated with the effect of amount of sand, autoclaving period, lime content on compressive .

Lime Based Steam Autoclaved Fly Ash Bricks Constr Build Mater (2007) M. Gutovic et al. Strength development in autoclaved blends made with OPC and clay-brick waste. Constr Build Mater (2005) Feng-qing Zhao et al. Activated fly ash/slag blended cement. Resour Conserv Recy (2007) Shen Xiaodong The compressive strength of brick samples containing 30% fly ash, 30% bottom ash and 15% fly ash-15% bottom ash was found to be 35.2, 8.0, 14.8 and 11.5 MPa, respectively.

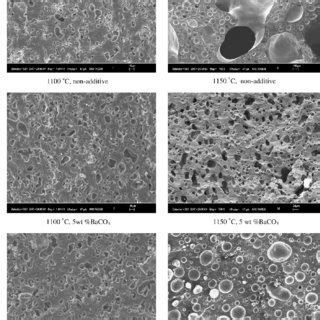

Over the years, research has been carried out to incorporate industrial by-products to produce autoclaved lime-sand brick. In particular, researchers have explored the possibility of incorporating fly ash to produce autoclaved lime-sand bricks [9], [10].Qin et al. [11] explored the usage of waste lime mud from papermaking process as source of lime as well as fly ash to . In this study, Seyitömer power plant fly ash was investigated in the production of light weight bricks. Fly ash, sand and hydrated lime mixtures were steam autoclaved under different test .

According to the autoclaved lime-sand bricks standard (GB 11945-1999), the autoclaved bricks from EMR meet the size, strength, freezing and thawing cycle number requirements of MU25 grade. . Lime based steam autoclaved fly ash bricks. Constr. Build. Mater., 21 (2007), pp. 1295-1300. View PDF View article View in Scopus Google Scholar. .from publication: Lime based steam autoclaved fly ash bricks | About 10 million tonnes of fly ash are produced yearly as waste from coal fired thermal power plants in Turkey. The increasing production of coal fly ash and the environmental problems associated with it has prompted various studies on its utilisation as an alternative ingredient to masonry products. Tests on bricks made of 100% fly ash manufactured using a technology similar to those used in normal clay bricks, has shown that their mechanical properties exceed those . Lime based steam autoclaved fly ash bricks. Constr Build Mater, 21 (2007), pp. 1295-1300. View PDF View article View in Scopus Google Scholar [13] C.D. Lawrence. Mortar expansions due to delayed ettringite and formation. Effect of curing period and temperature. Cem Concr Res, 25 (4) (1995), p. 903.

DOI: 10.1016/J.CONBUILDMAT.2012.03.006 Corpus ID: 136993911; Use of circulating fluidized bed combustion fly ash and slag in autoclaved brick @article{Zhang2012UseOC, title={Use of circulating fluidized bed combustion fly ash and slag in autoclaved brick}, author={Zhiwei Zhang and Jueshi Qian and Chao You and Changhua Hu}, . Choosing 1 m3 of autoclaved aerated fly ash and concrete block product as functional unit and “cradle to gate” as system boundary, a life cycle inventory is developed. . Key processes are fly ash slurry production, lime grinding, and steam curing processes. These processes account for 46.58%, 26.00%, and 19.62% of the total environmental .

Lime based steam autoclaved fly ash bricks. T. Çiçek M. Tanrıverdi. Environmental Science, Engineering. 2007; 125. Save. Preparation of high strength autoclaved bricks from hematite tailings. Yunliang Zhao Yi-min Zhang Tie-jun Chen Yongliang Chen Shenxu Bao. Materials Science, Engineering. 2012; 78. Mechanical strength and water absorption properties of autoclaved fly ash-lime bricks, TMMOB, Chamber of Civil Engineers’ Publication, Vol. 1, pp. 385-394. [8] Cicek, T. and Tanrıverdi, M. 2007. Lime based steam autoclaved fly ash bricks, Construction and Building Materials, Vol. 21, pp. 1295-1300.

7180 chemistry analyzer

mindray ba 88a semi-auto biochemistry analyzer

These high-quality pluggers have a shape that closely matches the final root canal preparation. This maximizes condensation forces on the softened gutta percha without placing undue stress on the root canal system.

lime based steam autoclaved fly ash bricks|seyitömer fly ash